As a result of studying this chapter, the student should:

know

- the essence of concepts characterizing the supply chain and the supply chain management process;

- relationships between strategic, tactical and operational levels of supply chain planning;

- supply chain planning technology;

be able to

- apply knowledge to supply chain management;

- organize the supply chain planning process;

own

- supply chain planning methods;

- an idea of the role and place of integrated planning in the supply chain management circuit.

Supply chain management and the place of integrated planning in the management loop

The supply chain is a complex economic system that consists of many manufacturing enterprises (producers), suppliers of raw materials and supplies, warehouse terminals, distributors, 3P and 4PL providers that have certain functionality and interact in material, financial and information flows, as well as service flows from sources of raw materials to the final consumer. The main elements (participants) of the supply chain are presented in Fig. 2.1.

Rice. 2.1.

– material flow; – information flow

As a rule, supply chains are complex stochastic systems with a number of features. These features include primarily:

- plurality of participants, and legally independent ones;

- the complex nature of the interaction between participants, who often compete with each other;

- each enterprise has its own target function, conflicting interests of enterprises;

- constant and rapid emergence, maintenance and disintegration of connections in chains;

- large quantity and variety logistics operations and functions performed by supply chain participants;

- cooperation and coordination relations with external suppliers and clients;

- the difficult to formalize qualitative nature of the relationships and criteria for the functioning of enterprises;

- the stochastic nature of most factors and processes that impede the functioning of enterprises and the supply chain as a whole.

The characteristics of the supply chain dictate the need to form a special management system that would ensure effective coordination joint activities supply chain enterprises and synchronization of their business processes. In the early 1980s. American companies i2 Technologies And Arthur Andersen introduced the term “supply chain management” (SCM) into economic practice. Supply chain management is understood as a new business strategy aimed at destroying obstacles, bureaucratic barriers and boundaries encountered in the movement of material, financial, and information flows among various participants in the supply chain. It is important that the point of view of one enterprise is transmitted to the entire chain. The synergy of cooperation is at the center, and the boundaries of enterprises become fluid, not limited only to the enterprise itself. Constantly changing environment requires flexible and rapid coordination of processes that extend beyond the boundaries of one enterprise. The collaborative work required for this, flexible only in content, but rigid in time, can be carried out outside the local organization, but within the framework of supply chain management.

For enterprises, implementing this strategy means conducting business on the principles of strategic interaction with their external suppliers and customers.

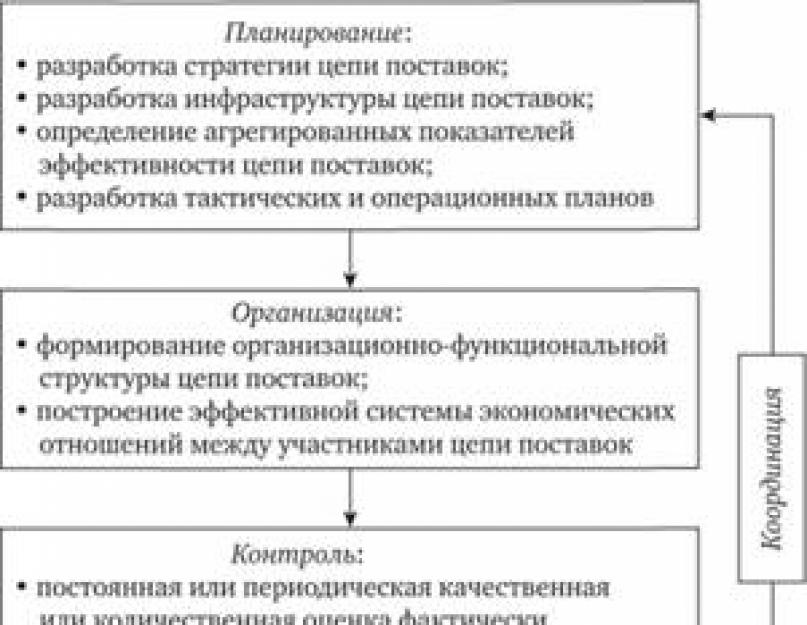

Supply chain management involves performing the functions of organizing, controlling, coordinating and planning the supply chain (Figure 2.2).

The function of the organization includes the formation of the structure of the supply chain, as well as the creation of a system of cooperative relations in the process of bringing the material flow from the source of its origin to the final consumer, which ensures the competitiveness of the supply chain. However, these connections are formed in a decentralized manner at each part of the supply chain. Each enterprise independently manages interactions with its suppliers and customers.

The nature of connections and interactions can be different, as it depends on the goals of the supply chain and on the characteristics of the products for the creation and promotion of which the chain was formed.

At the same time, organization is the process of implementing plans developed during the planning process.

Rice. 2.2.

Control function lies in objective quantitative and qualitative assessment supply chain performance results for subsequent adequate corrective action.

Supply chain control is a system for monitoring, detecting and resolving emerging problems in the functioning of the supply chain. Control is exercised over the network of partners, resources and processes in the supply chain to analyze and evaluate their effectiveness. The control system allows you to track every step at all levels of creating wealth and benefits (from the supply of raw materials to after-sales service to the end consumer).

The control process consists of setting standards, measuring actual results achieved, and making adjustments if the results achieved differ significantly from the established standards. The standards are based on plans developed during the planning process.

Coordination is a management function that ensures the smoothness and continuity of logistics processes in the supply chain. the main task coordination is to achieve consistency in the work of all parts of the organization by establishing rational communications between them.

Without appropriate coordination, supply chain businesses may focus on their own interests rather than the interests of the supply chain as a whole.

The formation of common goals and a common direction of efforts of all members of the supply chain to achieve these goals ensures planning function. Planning is included in all other management functions and serves as their necessary component, due to which it is customary to talk about its “omnipresence”. Planning at the same time co-organizes all other functions, giving them, and therefore the entire management as a whole, the necessary degree of organization. Planning is a fundamental management function.

The integrated planning process allows you to more clearly formulate supply chain goals and use a system of performance indicators necessary for subsequent monitoring of results. In addition, integrated planning ensures clearer coordination of joint activities of enterprises, synchronization of all business processes of enterprises, and thus strengthens the interaction of all participants in the supply chain. Planning allows you to increase customer satisfaction with the chain's activities. This means that planning is a continuous process of exploring new ways and methods of improving supply chain activities through identified opportunities, conditions and factors.

The term SCM (Supply Chain Management) has been used in the West for more than 15 years, but to this day there is no consensus among logistics and general management experts on the definition of this concept. Most view SCM from an operational point of view, understanding SCM as material flows. Others believe that SCM is a management concept, and finally, others mean by SCM the implementation of this concept in the enterprise.

The most common definitions of SCM are:

SCM is a set of approaches that helps effectively integrate suppliers, manufacturers, distributors and sellers. SCM, taking into account the service requirements of customers, allows us to ensure the availability the desired product at the right time in the right place at minimal cost.

SCM is the process of organizing planning, execution and control of the flow of raw materials, materials, work in progress, finished products, as well as providing efficient and fast service by obtaining operational information about the movement of goods. With the help of SCM, the tasks of coordinating, planning and managing the processes of supply, production, warehousing and delivery of goods and services are solved.

The supply chain involves both the organization itself and all suppliers and consumers of goods. (Fig.1)

Rice. 1. Participants of “Supply Chain Management”

The supply chain consists of many links interconnected by information, money and commodity flows. The supply chain begins with the acquisition of raw materials from suppliers and ends with the sale of finished goods and services to the customer. Some units may belong entirely to one organization, others to counterparty companies (clients, suppliers and distributors). Therefore, a supply chain always involves multiple organizations. (Fig.2)

Fig.2. Supply Chain Management cycle

1.2. Supply chain management

Each company sets itself more and more new tasks due to the rapid development of the market, tougher competition, and the requirement to improve the quality of customer service. To enhance its advantages and maintain competitiveness, a modern enterprise needs to optimize all value creation processes - from the supply of raw materials to service to the end consumer. To solve these problems, company management turns to SCM solutions.

Supply Chain Management includes the following stages:

Planning (PLAN)

In this process, sources of supply are identified, consumer demand is prioritized and generalized, inventories are planned, requirements for the distribution system are identified, as well as production volumes, supplies of raw materials, materials and finished products.

The problem of producing it yourself or buying it should be resolved at this stage. Decisions related to all types of resource planning and product life cycle management are also made at this stage. These processes balance demand and supply to develop courses of action that best meet Source, Make, Deliver requirements.

Procurement (SOURCE)

In this category, the main elements of supply management are identified, the quality of supplies is checked, the assessment and selection of suppliers is carried out, and contracts with suppliers are concluded. This also includes processes related to the receipt of materials: acquisition, receipt, transportation, similar control, placement on hold (storage). It is important to note that activities to manage the supply of goods and services must correspond to planned or current demand.

Production (MAKE)

This process includes production, execution and management of structural elements, management of production facilities (equipment, buildings, etc.), production quality, production cycles, production shift scheduling, etc. Specific production procedures are also determined: quality control, actual production procedures and cycles, packaging, storage and release of products (intra-plant logistics). All components of the process of processing the initial product into finished products must correspond to planned or current demand.

Delivery (DELIVER)

This process includes managing orders, warehouse and transportation. Order management includes creating and registering orders, selecting product configurations, creating prices, as well as creating and maintaining a customer base and managing debtors and creditors. Warehouse management involves the activities of picking and picking, packing, creating special packaging, customer labeling and shipping of goods. The transportation and delivery management infrastructure is determined by the rules for managing channels and orders, regulating goods flows for delivery, and managing delivery quality.

All these processes, inventory management, transportation and distribution must be aligned with planned or current demand.

Return (RETURN)

This process defines the structural elements of product returns (defective, surplus, requiring repair) both from made to source (make to source) and from delivery (deliver): determining the condition of the product, its placement, request for return authorization, scheduling of returns , direction for destruction and processing.

SCM processes can also be divided into two large groups: Supply Chain Planning (SCP) and Supply Chain Execution (SCE). SCP includes strategic planning of the supply chain or business processes in its individual links. SCE involves the implementation of plans and operational management of parts of the supply chain, such as transport or warehousing.

Optimizing supply chain management can solve the following problems:

Reducing the planning cycle and increasing the planning horizon by obtaining reliable and timely information;

Cost optimization due to the ability to identify strategic counterparties, the optimal selection of purchased products, as well as their suppliers, and support interaction with them in real time;

Reducing production costs through optimization of product flows and prompt organization of information exchange between contractors. Real-time communication between various supply chain participants helps prevent bottlenecks in the production process;

Reducing warehouse costs by aligning production volumes with demand. This task corresponds to the concept of supply management Just-In-Time (“just in time”);

Improving the quality of customer service is achieved through the efficiency and flexibility of the delivery process.

1.1. Supply chain management: economic essence, meaning and role in the modern economy

Modern science offers many different op-

definitions of the concept Supply Chain Management (SCM) - “Manage-

supply chain management”, while the range of opinions is very wide and depends on the country, the logistics school (direction) and the specific researcher. Today there is no consensus on the content of the concept of “supply chain management”; it is constantly being refined and changed. A synthetic definition of a supply chain, based on a generalization of the opinions of the majority of foreign scientists and specialists, may sound as follows: “A supply chain is three or more economic units (organizations or individuals) directly involved in external and internal flows of products, services, finance and/ or information from source to consumer."

Currently, the emphasis in the interpretation of this concept is increasingly shifting towards an expanded understanding

Supply Chain Management (SCM), given in the collection

"Standards for Logistics and Supply Chain Management."

Supply Chain Management (SCM) is the organization, planning, control and execution of the flow of goods, from design and procurement through production and distribution to the final consumer in accordance with market requirements for efficiency on demand.

spending. Logistics is the planning, execution and control of the movement and placement of people and/or goods, as well as the supporting activities associated with such movement and placement, within economic system created to achieve its specific goals.

There are many examples of different interpretations of the terms “supply chain management” and “logistics”. It is quite difficult to cover the entire spectrum of these interpretations, consisting of many different types, changing terms of logistics and supply chain management. There are a number of reasons that led to this state of affairs:

1. Historically short development time. Both logistics and supply chain management are fairly young and rapidly developing sciences. The term Supply Chain Management was first proposed in 80s of the XX century. The terminology and conceptual apparatus in this area of knowledge are constantly being refined and changed, filled with new content.

2. The presence of various national schools and trends in logistics and supply chain management. Currently, we can talk about the existence of an American school ( D. Bau-

Ersox, J. Closs, D. Waters, J. Stock, D. Lambert, etc.),

serious research in various European countries, V

including Great Britain ( M. Christopher, J. Mentzer, K. Oliver, M. Weber and etc.). Of particular interest are the studies of Australian scientists who have a significant influence on the development of the Asian logistics school. In particular, works John Gathorna recognized world-class specialist in the field of logistics and Supply Chain Management from Australia have been translated into Japanese and Chinese and are now widely recognized in Asian countries.

3. The interdisciplinary nature of logistics and supply chain management and the combination of economic and engineering disciplines in them. Over the past few decades, supply chain management has been one of the most dynamically developing concepts at the intersection of marketing, logistics, operational management And strategic management.

4. The presence of a large number of terms from various fields of knowledge. This is also due to the fact that leading experts in this field of knowledge are initially specialists in other areas: management, marketing, commerce, various engineering and technical specialties.

5. The absence of some logistics terms in various languages, as well as their inaccurate understanding in different countries. The use of different terminology can be explained by the authors’ belonging to one or another logistics school, as well as the desire to focus on certain aspects of the logistics process. For example, the term “physical distribution” was used in the USA in the second half of the 20th century as a synonym for the modern concept of logistics, and in the present

Currently, it denotes one of the functional areas of logistics and is synonymous with the term “distribution.”

1.2. Evolution of the concept of supply chain management

The concept of supply chain management has been one of the most dynamically developing areas of scientific and practical activity over the past decades.

The term "Supply chain management - SCM" - "Supply Chain Management" - was proposed by a system integrator - the company "i2 Technologies" and a consulting company "Arthur Andersen" in the early 1980s. The emergence of the concept of supply chain management is also associated with article K. Oli-

Vera and M. Weber “Supply chain management: Logistics Catches up with Strategy”, published by them in London in 1982.

IN In the process of evolution, the conceptual apparatus of the concept of supply chain management has changed significantly, because its terminology is constantly evolving. IN In the 80s of the last century, in countries with developed economies, a situation arose in many industries in which the cost of production decreased as much as was practically possible. To maintain competitiveness, there is a need for a new business management concept. With the emergence of the concept of “supply chain management” in the 1980s. The idea arose of coordinating the flow of materials and finished products not only within one company, but also in a number of companies interconnected by a technological chain. Therefore, it has become clear to many foreign companies that effective supply chain management is the next step they need to improve their competitiveness.

IN In the process of studying the theory and practice of the concept of supply chain management, four main stages in its development can be distinguished (Table 1.1).

Table 1.1

Evolution of the concept of supply chain management

Characteristic | |||||||||

Stage 1. Zaro- | Arises | necessity | |||||||

concepts | management |

||||||||

business as ideas for coordination |

|||||||||

tions of material flows and go- |

|||||||||

products | |||||||||

within the same company, but also within |

|||||||||

a number of companies connected between |

|||||||||

constitutes a technological chain |

|||||||||

coy. At this stage of development |

|||||||||

concept of "management" | |||||||||

supplies" in terms of content |

|||||||||

only slightly from |

|||||||||

was identified | expanded |

||||||||

interpretations | integrated |

||||||||

logistics and almost completely |

|||||||||

was determined by her | |||||||||

Stage 2. Dept. | First half | Happening | separation |

||||||

theory | wines of the 1990s | theories of Supply Chain Management- |

|||||||

ment from logistics, appear- |

|||||||||

xia independent | |||||||||

from logistics | management | ||||||||

supplies as science, as well as |

|||||||||

regions | use | ||||||||

concepts | practical |

||||||||

activities. | Happening |

||||||||

displacement and separation between |

|||||||||

do logistics and SCM understand- |

|||||||||

individual terms. Fuss- |

|||||||||

shows the need for a system |

|||||||||

matization | applied | ||||||||

concepts and terms of logistics and |

|||||||||

supply chain management |

|||||||||

Continuation of the table. 1.1 |

||||||||

Stage 3. For- | The difference is clearly marked |

|||||||

mation | wines of the 1990s – | between integrated logic |

||||||

classical | stick and circuit control |

|||||||

concepts | supplies, control functions |

|||||||

ling, coordination and integration |

||||||||

tions in product management |

||||||||

the flow is assigned to the |

||||||||

"control | ||||||||

supplies." Main directions |

||||||||

research concentration |

||||||||

are sharpened on the processes of in- |

||||||||

integration and creation of strategic |

||||||||

partner | ||||||||

tions, as well as ensuring |

||||||||

relationship and control of |

||||||||

Variety flows and information |

||||||||

functional coordination to ensure |

||||||||

baking communications between |

||||||||

chain links. Total accumulation |

||||||||

extensive experience of theoretical and |

||||||||

practical knowledge | ||||||||

runs training courses on new |

||||||||

discipline | ||||||||

Stage 4. Co- | There is an even deeper |

|||||||

temporary | wines of the 2000s | study | ||||||

development stage | and chain management practices |

|||||||

supplies and their adaptation to |

||||||||

markets. Modern |

||||||||

practice | management | |||||||

supplies | focuses on |

|||||||

internal company planning |

||||||||

resource optimization |

||||||||

building relationships |

||||||||

exchanges between the focal com- |

||||||||

company and other members |

||||||||

supply chain | ||||||||

1.3. Development of the concept of supply chain management

Currently, supply chain management as a SCM concept is one of effective ways increasing profits and market share and is actively being implemented in the economies of industrialized countries. Many large companies, including Russian ones, are introducing the principles of Supply chain management as a new business ideology. The introduction and development of strategic advantages of logistics both abroad and in our country is facilitated by national coordinating

common organs such as European Logistics Association

(European Logistics Association - ELA) and the Council of Supply Chain Management Professionals (CSCMP). In the Russian Federation, the role of such coordinators is currently played by National

National Logistics Association of Russia (NLA) and National Supply Chain Council . The need for the creation and functioning of these organizations is to:

- develop proposals and additions to legislative and regulatory legal acts of the Russian Federation in terms of logistics, since there is currently no legislation in the field of logistics in our country;

- eliminate barriers existing in tax, customs, transport legislation Russia, which impede the effective use of the strategic potential of logistics;

- form integrated logistics systems, covering various areas of business, to create interregional and international integrated logistics transport, trade and information systems.

National Supply Chain Council – public non-profit organization in the form of a non-profit partnership open to all market participants ( industrial enterprises, suppliers of products and services, transport and logistics companies, financial and credit organizations, insurance organizations, non-profit associations and centers, consulting, educational and state enterprises). The main goal is to disseminate supply chain management standards in practice real business in the Russian Federation and CIS countries. The mission of the Supply Chain Council is to develop,

development and dissemination of the supply chain model as the basis of an all-Russian inter-industry standard for supply chain management, combining the best global and national practices. The supply chain model defines the general concept of supply chains, standard terminology, a system of measurements and assessments of the logistics function, and generalizes best practics, is a procedural model for implementing logistics software, performs an integrating function in the construction of both intra-corporate and inter-corporate supply chains.

The National Logistics Association of Russia pre-

constitutes public organization, whose founders are State University– Higher School of Economics (SU-HSE), Russian Association of Business Education (RABO) and the Association of Forwarders of St. Petersburg. The mission of NLA is the formation and development of logistics in Russia as a new scientific and practical direction that contributes to the socio-economic development of business entities, economic sectors and the country as a whole, as well as improving the well-being of citizens. Among the main tasks of the organization are the following:

- analysis of foreign theoretical research and practical experience in the field of logistics with the aim of their adaptation and implementation in Russia;

- development of proposals and additions to legislative and regulatory legal acts of the Russian Federation in terms of logistics;

- coordination of the activities of enterprises, organizations and institutions engaged in research in the field of design, construction and maintenance of the functioning of logistics systems; exchange of best practices in the use of logistics developments

in the Russian Federation and abroad;

- organization and participation in the certification procedure for logistics specialists in accordance with Russian and international requirements and standards.

Growing globalization, interaction with Western companies, as well as domestic research and publications in the field of logistics and supply chain management make it possible to use global experience in practice. Many foreign companies, expanding the geography of supply chains, include the territory of the Russian Federation as markets for finished products, as well as with

purpose of placement production capacity for its production, into its own supply chain, thus involving Russian partners in global integration.

As an example, we can consider the activities of Electrolux. This company is one of the largest players in the washing machine market. According to the annual ranking of Fortune magazine, Electrolux is one of the hundred largest companies in the world. Electrolux has been operating on the Russian market since 2004. In order to gain a position in a new rapidly growing sales market as quickly as possible household appliances the company opened its own factory for the production of Electrolux and Zanussi washing machines in St. Petersburg. An important indicator of the plant’s activity is the degree of localization of component production. Localization of production refers to the practice of placing a company's production facilities in close proximity to the sources of their consumption. From the standpoint of logistics and customs, the feasibility of opening a factory in Russia to meet the needs of the growing domestic market is obvious. When importing ready-to-use washing machines, you must pay customs duties at the import rate customs duty 15% of the customs value of the product in euros or US dollars. Since March 2005, by Decree of the Government of the Russian Federation No. 125 “On Amendments to the Customs Tariff of the Russian Federation in relation to components for washing machines,” a zero duty rate was established for parts of washing machines (RF HS code 8450 90 000 0). Thus, some components for the production of washing machines began to be imported at a zero duty rate, which made it possible to significantly reduce costs.

Another example of the involvement of Russian potential in global integration is the experience of the Ford automobile concern. In 2002, the official opening of the Ford plant took place in the city of Vsevolozhsk, Leningrad region. The operation of the plant provided for the company's fulfillment of obligations regarding a certain level of investment in the implementation of the project and phased localization of products. To date, Ford's investment in the Russian project has amounted to about $230 million. The level of localization of the plant's products is more than 40% of the cost of the car.

Currently, supply chain management as a SCM concept is one of the effective ways to increase profits and market share and is being actively implemented in the economies of industrialized countries. Many large companies, including Russian ones, are introducing the principles of Supply chain management as a new business ideology. The introduction and development of strategic advantages of logistics both abroad and in our country is facilitated by national coordinating bodies, such as the European Logistics Association (ELA) and the Council of Supply Chain Management Professionals (CSCMP) . In the Russian Federation, the National Logistics Association of Russia (NLA) and the National Supply Chain Council currently act as such coordinators. The need for the creation and functioning of these organizations is to:

Develop proposals and additions to the legislative and regulatory acts of the Russian Federation in terms of logistics, since currently there is no legislation in the field of logistics in our country;

Eliminate barriers existing in Russian tax, customs, and transport legislation that impede the effective use of the strategic potential of logistics;

To form integrated logistics systems covering various areas of business, to create interregional and international integrated logistics transport, trade and information systems.

The National Supply Chain Council is a public non-profit organization in the form of a non-profit partnership, open to all market participants (industrial enterprises, suppliers of products and services, transport and logistics companies, financial and credit organizations, insurance organizations, non-profit associations and centers, consulting, training and state enterprises).

The main goal is to disseminate supply chain management standards in real business practice in the Russian Federation and the CIS countries. The mission of the Supply Chain Council is to develop, develop and disseminate the supply chain model as the basis of a nationwide cross-industry standard for supply chain management that combines best global and national practices. The supply chain model defines the general concept of supply chains, standard terminology, a system of measurements and assessments of the logistics function, summarizes best practices, is a procedural model for the implementation of logistics software, and performs an integrating function in the construction of both intra-corporate and inter-corporate supply chains. Popova L.V. “Controlling” // - M.: Business and Service, 2010 - P. 68.

The National Logistics Association of Russia is a public organization whose founders are the State University - Higher School of Economics (SU-HSE), the Russian Association of Business Education (RABO) and the Association of Forwarders of St. Petersburg.

The mission of NLA is the formation and development of logistics in Russia as a new scientific and practical direction that contributes to the socio-economic development of business entities, economic sectors and the country as a whole, as well as improving the well-being of citizens. Among the main tasks of the organization are the following:

Analysis of foreign theoretical research and practical experience in the field of logistics with the aim of their adaptation and implementation in Russia;

Development of proposals and additions to legislative and regulatory acts of the Russian Federation in terms of logistics;

Coordination of the activities of enterprises, organizations and institutions engaged in research in the field of design, construction and maintenance of the functioning of logistics systems;

Exchange of best practices in the use of logistics developments in the Russian Federation and abroad;

Organization and participation in the certification procedure for logistics specialists in accordance with Russian and international requirements and standards.

Growing globalization, interaction with Western companies, as well as domestic research and publications in the field of logistics and supply chain management make it possible to use global experience in practice. Many foreign companies, expanding the geography of their supply chains, include the territory of the Russian Federation as markets for finished products, as well as in order to locate production facilities for their manufacture, in their own supply chain, thus involving Russian partners in global integration.

As an example, we can consider the activities of Electrolux. This company is one of the largest players in the washing machine market. According to the annual ranking of Fortune magazine, Electrolux is one of the hundred largest companies in the world. Electrolux has been operating on the Russian market since 2004.

In order to quickly gain a position in the new rapidly growing market for household appliances, the company opened its own factory for the production of Electrolux and Zanussi washing machines in St. Petersburg. An important indicator of the plant’s activity is the degree of localization of component production. Localization of production refers to the practice of placing a company's production facilities in close proximity to the sources of their consumption. From the standpoint of logistics and customs, the feasibility of opening a factory in Russia to meet the needs of the growing domestic market is obvious. When importing ready-to-use washing machines, you must pay customs duties at an import customs duty rate of 15% of the customs value of the product in euros or US dollars.

Another example of the involvement of Russian potential in global integration is the experience of the Ford automobile concern. In 2002, the official opening of the Ford plant took place in the city of Vsevolozhsk, Leningrad region. The operation of the plant provided for the company's fulfillment of obligations regarding a certain level of investment in the implementation of the project and phased localization of products. To date, Ford's investment in the Russian project has amounted to about $230 million. The level of localization of the plant's products is more than 40% of the cost of the car.

Another way to get involved Russian business The creation and development of Russian companies’ own supply chains and their inclusion, thus, in global supply chains became part of global integration processes.

One of the striking examples is the Baltika brewing company, which is a leader Russian market brewing products and one of the world leaders in beer sales (according to Rosstat and the company’s own sources).

The Baltika company considers logistics as one of the most significant reserves for creating additional competitive advantages. In 2006, projects such as warehouse automation, transfer to direct deliveries to distributors and organization of consignment storage of products were implemented and started on the principles of logistics and supply chain management. In addition, active work was carried out to optimize loading Vehicle, routing, as well as improving the production and shipment planning system. A project was launched in collaboration with JMAC to improve business processes and create an industry-leading supply chain.

In recent years, the topic of SCM has been on the agenda of many business conferences, workshops and is reflected in specialized business publications.

Now that the period of getting used to the SCM concept has already passed, the question of the prospects for perceiving the principles of supply chain management and implementing corresponding SCM solutions in Russian conditions becomes more relevant. IT industry specialists and managers do not have a common opinion about the relevance of SCM in the context of the ineffective logistics infrastructure of the domestic economy.

Partly due to the fact that the SCM concept was actively promoted in Russia primarily by corporate IS suppliers, SCM terminology is associated with specific information solutions. However, in order to clearly indicate the place of SCM in the company’s operational and information strategy, it should be remembered that all these MRP, ERP, SCM, SCE and other mysterious abbreviations are not primarily information systems of one type or another, but management concepts and strategies based on certain business imperatives. The concept of managing a business as a supply chain has existed in a fairly mature form for about 20 years and has many interpretations. “As a result of the emergence of a new generation of SCM products, supply chain management systems already include all business applications focused on developing strategy, coordinating planning and organizing management in the field of supply, production, warehousing and delivery of goods to the end consumer.” Makarenko V. Project “Warehouse networks” // STS Logistics, 2011.

How realistic is it to expect results as brilliant as in the West from the implementation of supply chain management principles in Russian companies?

On the one hand, for such advanced technologies, as SCM, fertile soil has formed in Russia. Already, many domestic manufacturers and distributors are faced with increasing competition from international companies invading our market, rising costs for warehouse and transport logistics and the need to establish direct relationships with suppliers and customers. World leaders use SCM to achieve competitive advantages in front of the second and third tier players. They follow a similar strategy in Russia. Understanding this, the leaders Russian companies are looking at SCM as a way to build a business that is competitive in the global market. The level of automation of many companies, especially in industries such as retail and distribution is quite high - sometimes even higher than in developed countries, including the homeland of SCM in the USA. A considerable part of such companies have modern corporate networks, connecting Main office with regional branches and offices.

On the other hand, building an effective supply chain in Russian conditions is considered by many foreign experts to be an elusive and even premature goal. The reasons are known: since the level of trust between domestic companies - potential partners in the supply chain is still low, customs legislation complicates effective organization movement of goods, and management in geographically distributed holdings still rarely covers such operational tasks as procurement, logistics and sales. All this makes it difficult to coordinate the development of a business as a supply chain, which also includes third-party suppliers and distributors, and, therefore, narrows the scope of the SCM concept, reducing it to a few vertically integrated Russian holdings that mainly build their own distribution and logistics chains.

There is even an opinion that only large companies with an extensive network of distributors and suppliers need SCM systems.

It is believed that such solutions are a kind of hi-end in business that only a few leaders can afford, and to implement an SCM solution you must have a working ERP system.

The domestic market can be divided into two main areas - solutions from Russian developers and Western solutions.

If we talk about Western solutions, we can note the Renaissance, Axapta and a number of others systems sold on the domestic market.

The Renaissance system, sold by Interface, is a solution that allows you to store, use and analyze company information in various areas.

The system includes the Renaissance Distribution and Renaissance Transport Manager subsystems. Like most Western solutions, Renaissance Distribution is a comprehensive SCM solution that allows you to create a single information space for all services involved in the sales process. The solution is aimed at collecting and analyzing all statistical data on demand, on the basis of which further deliveries of goods are planned, relations with suppliers and distributors are regulated and adjusted production plans enterprises.

Renaissance Transport Manager allows the company to draw up an operational transportation plan, plan transportation, and monitor the movement of goods. As a result of using Transport manager, a company can draw up a transportation plan in advance, determine the time of delivery of goods to customers, and reduce transport costs. The database will allow the company to have up-to-date information on goods that are in transit and to prepare documentation for transportation.

It is perhaps the first ERP system that is completely Internet-oriented. The system integrates SCM solutions that allow the company to track the entire process of selling a product from issuing an offer to issuing an invoice for the supply of products and monitoring warehouse inventory to fulfill the order. The system also allows for planning, dividing the planning period into components, order processing and fulfillment, warehouse distribution and management, transportation management, production logistics, etc. In the future, the creators plan to develop SCM solutions, providing customers with additional opportunities.

Domestic developers, like many Western ones, see supply chain management as one of the goals of an enterprise, and therefore offer tools that are implemented into the overall enterprise management system. It is also worth noting that for Russian programs characterized by an emphasis on financial activities enterprises and accounting. That is why the tools included in some solutions imply the automatic generation of accounting documentation - invoices, payment orders, invoices. Of course, this is an important point in SCM solutions, which must be associated with financial services, however, as the experience of the Western market shows, it is far from the only one.

At the same time, it cannot be said that domestic solutions do not offer any mechanisms for supply chain management.

Tools that allow you to manage logistics processes are included, for example, in the Boss Corporation system (developed by IT). The subsystem allows the company to create an inventory management scheme, and also includes mechanisms that allow the company to customize logistics business processes according to its needs.

It is also worth noting the solution of the Intellect-Service company - "BEST-enterprise", which contains tools for managing the warehouse, purchasing and sales activities of the enterprise. The mechanisms offered by the BEST program are to maintain all documentation related to trade and purchasing activities, control the shipment and receipt of goods, maintain price lists with prices for the company's products and automate the receipt of orders from customers.

In covering domestic SCM solutions, one cannot fail to mention the decision of the Parus Corporation for corporate clients. The Logistics program included in the solution contains tools that allow you to manage operational processes and plan further sales activities. As elements that allow you to automate and optimize current processes, it is proposed to create and maintain all client and internal documentation, control the amount of free goods in the warehouse, as well as track all payments.

For further planning, the program contains tools that allow you to predict future demand for products and analyze trade turnover.

In addition to the logistics program, the corporation also offers a number of analytical tools that are aimed, among other things, at analysis in the field of SCM.

So, with the help of Parus-Analyst, the company receives information on trade turnover, sales leaders and can optimize its production plans according to consumer demand. In addition, thanks to this analytical tool, the company has the opportunity to adjust its sales policy.

Another opportunity that the company will receive is an analysis of internal activities - how successful was the organization of warehouse activities and the correctness of building trade relations.

In general, domestic solutions are characterized by the automation of internal company processes and solutions that use the Internet to optimize the work of companies are offered by a relatively small number of companies.

Therefore, the “Parus on-line” solution is also quite unique. Thanks to its use, the company is able to create a common information space and simplify the processes of orders and purchases. Thanks to this, the company gets the opportunity to integrate SCM solutions with CRM (Customer Relationship Management) and SRM (Supply Relationship Management). This allows the company to establish stable relationships with all categories of partners, increasing the level of customer satisfaction, and optimizing its sales activities according to demand.

It is also worth noting that a number of companies typically use their own developments or turn to small system integrators and development companies, which allow them to create individual solutions for monitoring and managing supplies.

Sheremetyevo-Cargo

At the end of 1998, an agreement was concluded with the IT company for the implementation of the Boss Corporation system, which we mentioned above, at Sheremetyevo-Cargo. By that time, Sheremetyevo-Cargo already had its own cargo management system, and with the help of the IT solution the company planned to integrate its own developments with automated systems accounting And financial analysis. The IT company offered Sheremetyevo-Cargo ample opportunities to refine and optimize the system, taking into account the specifics of the work and the needs of the enterprise. In the second half of 2000, Sheremetyevo-Cargo entered into an agreement with Diamond Communications to create a wireless access system information system and the use of barcoding systems. Thus, the cargo company gets the opportunity to control the movement of cargo and control cargo transportation at all stages of cargo transportation.

It is worth noting that on this moment not enough yet objective information about successfully implemented solutions. This is due not only to the fact that domestic companies use SCM solutions less frequently, but also to the fact that the terminology adopted in the West is still rarely used in Russia. Thus, we can conclude that currently Russian companies, along with their Western colleagues, can use or are already using the potential of the concept of logistics and supply chain management, which should help strengthen their competitiveness.

Objectives and strategic elements of supply chain management

The goal of SCM is to maximize the total value created by the supply chain. This value is defined as the difference between what the customer is willing to pay for the product and the costs that collectively arise in the CPU. For most CPUs, this metric can be called "CPU profitability", defined as the difference between the revenue received from the customer and the total costs in the CPU.

All SCM methods and tools for increasing company profits are aimed at achieving two main effects:

increasing income from product sales by increasing the level of service, accuracy of deliveries and forecasting demand;

reducing costs by reducing inventory levels, reducing overhead and transaction costs in purchasing, warehousing and distribution, and improving the utilization of production and logistics capacity.

The main economic effects of SCM are presented in Table 2.1.

The introduction of the concept of supply chain management is associated with the development of new organizational and functional schemes for interaction between enterprises. Completed projects on the implementation of supply chain management showed the possibility of reducing inventory levels by up to 60%, reducing production time by coordinating process chains by up to 50%, increasing profits by optimizing the value creation process and reducing transaction costs by up to 30%, improving product quality by up to 30%, increasing turnover and market share by increasing flexibility and speed of response and changing customer relationships by up to 55%. Figure 2.2 shows the main indicators (key indicators) for assessing the effectiveness of supply chain management.

Table 2.1.

Supply Chain Management Effectiveness

Rice. 2.2. Main indicators (key indicators) for assessing the effectiveness of supply chain management.

Supply chain management can be seen as a strategic balancing act between customer focus and profitable growth. In the supply chain, as well as in the participating enterprises, the organization of processes is purposefully structured with a focus on customer needs. Thus, a network of creation and sale of material goods and values arises, in which intra-organizational and inter-organizational connections are expressed in the “Client-Supplier” relationship. If we take into account the interests associated with customer focus and achieving effective growth, then two main aspects can be distinguished:

1) supply chain formation as a set of connections of flows of materials, goods, services and information from suppliers to clients;

2) optimal use of resources and cost reduction (since the goal of supply chain management is to increase profits).

An essential factor for success in a supply chain is to approach the process from a integral management, combining regulatory, strategic and operational indicators. From the point of view of the process of integration and coordination of the supply chain from the supplier to the final consumer, the main thing is to consider the total chain for the creation of material goods and values. Using the process orientation principle, it is necessary to determine how effectively processes throughout the supply chain are coordinated to create value for customers while increasing the profitability of each element in the supply chain.

Successful implementations of the supply chain management concept (from the point of view of economic growth) allow us to identify specific behavior patterns. To achieve the best level of performance and process management in the supply chain, the following principles must be considered:

Principle 1. Segmentation is implemented taking into account the focus on customers according to their service needs, including specific groups of customers.

Principle 2. Adapting the wealth chain takes into account the service and profitability requirements of all segments.

Principle 3. Requirements are planned throughout the supply chain to ensure optimal resource allocation.

Principle 4. Product differentiation occurs as it gets closer to customers.

Principle 5. Strategic sourcing management aims to reduce the total costs of materials and services.

Principle 6. Developing a technology implementation strategy targets the entire supply chain to enable multi-step decision making with a clear view of the flow of materials, goods, services and information.

Principle 7. The identification of changing indicators in the supply chain is aimed at ensuring effective and quality service end consumers.

As first important principle Successful supply chain management involves segmenting customers based on their service needs and targeting the chain at those segments to achieve benefits.

The second principle is an individual adaptation of the chain of creation of material goods and values in the context of service requirements, taking into account the profitability of the segment.

Third principle refers to needs planning. The implementation of this principle should be carried out throughout the supply chain, where forecasts are created and resources are allocated within the chain.

Subject fourth principle is to identify the client connection point, i.e. determining the place in the supply chain from which the distribution of orders from certain customers begins. The customer connection point should be as close to the customer as possible to shorten the time to differentiate the product based on the type of market. This makes it possible to smooth out fluctuations in demand, as well as avoid the costs of creating excess inventories. Additionally, reducing lead times throughout the supply chain improves demand response.

Fifth principle means an increase in the level of capital binding within the chain. The principle of “our supplier's costs are essentially our costs” shows that high costs from suppliers are indirectly passed on to the next link in the chain. Strategic supplier management aims to minimize these costs.

Important information technologies in supply chain management is stated in sixth principle, which means information support in operational and strategic management, for example, in production planning and further development of the chain of creation of material values and benefits.

Finally, the control of activities in the supply chain is reflected in seventh principle. To identify achieved goals, it is important to create a unified measurement tool within the supply chain.

The goal of the SCM concept is to achieve best results throughout the chain, optimizing the interests of all its participants. Thus, the system of goals includes, on the one hand, maximizing benefits for the client, and on the other, minimizing costs, which determines the competitiveness of the entire supply chain and its constant development.

The concept of supply chain management reflects an integrated approach in which supply chain management objectives are linked to a coherent concept of behavior. In the context of supply chain management, a shift in focus is required to collaboration across enterprise boundaries while respecting the autonomy of chain participants. Accordingly, the relative framework of integrated management operates in the supply chain to target both the enterprise level and the chain level as a total system.

Within SCM, it is important to distinguish between the goals, objectives and indicators of regulatory, strategic and operational management.

Regulatory management associated with the overall supply chain objectives, principles and norms aimed at ensuring its viability and efficiency. The need to ensure supply chain viability in competitive environment intertwined with the desire for further development of participating enterprises. From this point of view, political actions and processes related to the supply chain constitute the essential content of normative management. Regulatory management forms supply chain policies aimed at developing effective capabilities based on groups of requirements.

Operational management is to transform normative and strategic values into operational actions that are aimed at the effective and efficient execution of current, day-to-day processes associated with the movement of materials, information and funds.

Strategic management stems from the mission of normative management in supply chain policy. At the center of strategic management, along with programs, is the fundamental justification of structures and systems, as well as behavior in solving problems of participating enterprises. If regulatory management justifies the activity, then the strategic one directs it. Strategic management necessary to create, secure and use successful positions, because expresses a single market position of the entire supply chain. Successful positions represent the combined experience of participating enterprises, as well as the entire supply chain in the market in the field of technology, process management, culture of relationships, etc. Existing views reflect the place of the supply chain in the formation of market relations, and new ones are formed from the development of conditions conducive to achieving future benefits from competitive advantages.

The effectiveness of supply chain management can be summarized as market, intra-company and supplier effects.

Market effect. Supply chain management allows you to achieve long-term competitive advantages that arise from, for example, the ability of enterprises participating in the chain to concentrate on core activities, reducing market risks through effective coordination in the chain and a constant flow of information. Consistently focusing processes on customers and their desires makes it possible to increase the level of service and customer satisfaction. Integrated coordination in the supply chain makes it possible to reduce order fulfillment and delivery times and increase the level of trust and loyalty from consumers.

In addition, supply chain management promotes close cooperation between participating enterprises, accelerating innovation processes and development of new markets.

Intra-firm effect. Thanks to optimized forecasts of needs, supported by an information technology base, as well as the constant exchange of information about capacity and emerging bottlenecks, the supply chain management system creates transparency in information about the amount of inventory, sales volumes, lead times, etc. This makes it possible to significantly reduce inventory, increase productivity and infrastructure efficiency, optimize batch sizes, improve service levels and, finally, manage flows throughout the supply chain.

Benefits for suppliers. As part of customer-focused supply chain management, the use of information technology allows for the development of new markets, which enables suppliers to expand existing market boundaries.

Effective coordination of intra- and inter-organizational processes, with the potential benefits described above, is an important factor in significantly reducing process costs throughout the supply chain.