Date of introduction 1974-07-01

This standard establishes the basic requirements for the execution of drawings of parts, assembly, dimensional and installation at the stage of development of working documentation for all industries.

(Changed edition, Amendment No. 8,).

1. GENERAL REQUIREMENTS FOR WORKING DRAWINGS

1.1. General provisions

1.1.1. When developing working drawings, the following is provided:

a) optimal use of standard and purchased products, as well as products mastered by production and corresponding to the modern level of technology;

b) a rationally limited range of threads, splines and other structural elements, their sizes, coatings, etc.;

c) a rationally limited range of grades and assortments of materials, as well as the use of the cheapest and least scarce materials;

d) the necessary degree of interchangeability, the most advantageous methods of manufacturing and repairing products, as well as their maximum ease of maintenance in operation.

1.1.1a. Working drawings on paper (in paper form) and electronic drawings can be made on the basis of an electronic model of a part and an electronic model of an assembly unit ( GOST 2.052).

(Changed edition, Amendment No. 11)

General requirements for electronic documents- ByGOST 2.051

1.1.2. When referenced in drawings of serial and mass production for technical specifications, the latter must be registered in in the prescribed manner(in states where state registration technical specifications is required).

It is allowed to provide references to technological instructions when the requirements established by these instructions are the only ones that guarantee the required quality of the product; however, they must be included in the kit design documentation on the product when transferring it to another enterprise.

It is not allowed to provide references to documents defining the shape and dimensions of structural elements of products (chamfers, grooves, etc.) if the relevant standards do not contain a symbol for these elements. All data for their manufacture must be shown on the drawings.

(Changed edition, Amendment No. 4, 10, ).

1.1.3. It is not allowed to place technological instructions on working drawings. As an exception, the following is allowed:

a) indicate manufacturing and control methods, if they are the only ones that guarantee the required quality of the product, for example, joint processing, joint bending or flaring, etc.;

b) give instructions on the choice of the type of technological workpiece (casting, forging, etc.);

c) indicate a certain technological method that guarantees the provision of certain technical requirements to a product that cannot be expressed by objective indicators or quantities, for example, the aging process, vacuum impregnation, gluing technology, control, plunger pair coupling, etc.

1.1.4. For products of the main unit* and auxiliary production, on the drawings intended for use at a specific enterprise, it is allowed to place various instructions on the manufacturing technology and control of products.

* The rules for the execution of drawings of products of single production also apply to auxiliary production.

1.1.6. The dimensions of conventional signs that are not established in the standards are determined taking into account the clarity and clarity of the drawing and are kept the same when repeated many times.

1.1.7. The working drawing of the product indicates the dimensions, maximum deviations, surface roughness and other data that it must comply with before assembly (Fig. A).

The exception is the case specified in paragraph.

The dimensions, maximum deviations and surface roughness of product elements resulting from processing during or after assembly are indicated on the assembly drawing (Fig. b).

1.1.14. If an edge (edge) needs to be made sharp or rounded, then a corresponding indication is placed on the drawing. If there is no indication on the drawing about the shape of the edges or ribs, then they should be blunted.

If necessary, in this case you can specify the size of the bluntness (chamfer, radius), placed next to the “∟” sign, for example, dash. .

(Changed edition, Amendment No. 9).

1.2.6. In the drawing of a product obtained by cutting a workpiece into parts and interchangeable with any other product made from other workpieces according to this drawing, an image of the workpiece is not placed (Fig.).

1.2.7. For a product obtained by cutting a workpiece into parts or consisting of two or more jointly processed parts, used only together and not interchangeable with the same parts of another similar product, one drawing (drawing) is developed.

1.3. Drawings of products with additional processing or alteration

1.3.1. Drawings of products manufactured with additional processing of other products are carried out taking into account the following requirements:

a) the workpiece product is depicted with solid thin lines, and surfaces obtained by additional processing, newly introduced products and products installed to replace existing ones - with solid main lines.

The parts removed during alteration are not depicted;

b) apply only those dimensions, maximum deviations and surface roughness designations that are necessary for additional processing (Fig. ).

It is allowed to apply reference, overall and connecting dimensions. It is allowed to depict only part of the workpiece product, the elements of which must be additionally processed.

1.3.2. In the drawing of a part produced by additional processing of the workpiece, in the column 3 in the main inscription write the word “Blank product" and designation of the workpiece product.

Using purchased product as a blank product in column 3 of the main inscription indicate the name of the purchased product and its designation, which are contained in the accompanying documentation of the manufacturer (supplier).

(Changed edition, Amendment No. 11)

Parts drawings

The positions of the components included in the options will appear on the corresponding additional images (Fig. ).

3.3.14. In cases where individual parts of a purchased product are installed in different assembly units of the product (for example, tapered roller bearings), the purchased product is recorded in the specification of the assembly unit in which it is included in assembled form. The technical requirements of the assembly drawing of the product being developed indicate those assembly units that include individual parts of the purchased product. In the specifications of these assembly units, in the “Note” column indicate the designation of the specification that includes the purchased product in assembled form. In this case, in the “Name” column indicate the name of the component of the purchased product, and in the “Quantity” column. not filled in.

(Introduced additionally, Amendment No. 8).

4. DIMENSIONAL DRAWINGS

4.1. Dimensional drawings are not intended for the manufacture of products based on them and should not contain data for manufacturing and assembly.

4.2. In the dimensional drawing, the product is depicted with maximum simplification. The product is depicted so that the extreme positions of moving, extending or tilting parts, levers, carriages, hinged lids, etc. are visible.

It is allowed not to show elements that protrude beyond the main contour by an insignificant amount compared to the dimensions of the product.

4.3. The number of views on the dimensional drawing should be minimal, but sufficient to give a comprehensive idea of the external outlines of the product, the positions of its protruding parts (levers, flywheels, handles, buttons, etc.), and the elements that must always be in the field of view (for example, scales), about the location of the elements connecting the product with other products.

4.4. The image of the product on the dimensional drawing is made with solid main lines, and the outlines of moving parts in extreme positions are drawn with dash-dotted thin lines with two dots.

It is allowed to depict the extreme positions of moving parts in separate views.

(Changed edition, Amendment No. 3).

4.5. On the dimensional drawing it is allowed to depict parts and assembly units that are not part of the product using solid thin lines.

4.6. The overall dimensions of the product, installation and connecting dimensions and, if necessary, dimensions defining the position of the projecting parts.

Installation and connection dimensions required for connection with other products must be indicated with maximum deviations. It is allowed to indicate the coordinates of the center of mass. The dimensional drawing does not indicate that all dimensions given on it are for reference.

image of the mounted product;

images of products used during installation, as well as a full or partial image of the device (structure, foundation) to which the product is attached;

installation and connection dimensions with maximum deviations;

list of components required for installation;

technical requirements for product installation.

5.2. Installation drawings are produced at:

products mounted on one specific place (device, object, foundation);

products mounted on several different places (devices, objects).

An installation drawing is also produced in cases where it is necessary to show the connection of the components of the complex to each other at the site of operation.

5.3. The installation drawing is carried out according to the rules established for assembly drawings, taking into account the rules set out in this section.

5.4. The mounted product is depicted in the drawing in a simplified manner, showing its external outlines. They show in detail the structural elements that are necessary for proper installation of the product.

The device (object, foundation) to which the mounted product is attached is depicted in a simplified manner, showing only those parts that are necessary to correctly determine the location and method of fastening the product.

The image of the mounted product and the products included in the set of mounting parts is drawn with solid main lines, and the device to which the product is attached is drawn with solid thin lines.

When making foundation drawings, the foundation is depicted with solid main lines, and the mounted product with solid thin lines.

5.5. The installation drawing indicates the connecting, installation and other dimensions required for installation.

The installation drawing, intended for installing the product in various places, also indicates the dimensions that determine the specific requirements for the placement of the product (for example, the minimum distance to the wall of the room, etc.).

The installation drawing of the complex indicates the dimensions that determine the relative position of the components directly included in the complex.

5.6. The list of components required for installation can be made according to Form 1 GOST 2.106 , with the exception of the “Format” and “Zone” columns, and should be placed on the first sheet of the drawing.

)

)

5.8. Products and materials required for installation that are not supplied with the product being mounted are listed on the installation drawing, and the corresponding indication is placed in the “Note” column or in the technical requirements, for example: “Pos. 7 And 9 are not supplied with the product”, etc.

If it is impossible to indicate the exact designations and names of non-supplied products, then their approximate names are indicated in the list, and in the drawing, if necessary, dimensions and other data that ensure the correct selection of products required for installation.

5.9. On the installation drawing on the shelf, leader lines or directly on the image indicate the name and (or) designation of the device (object) or part of the device to which the mounted product is attached.

INFORMATION DATA

1. DEVELOPED AND INTRODUCEDState Committee of Standards of the Council of Ministers of the USSR

2. APPROVED AND ENTERED INACTION By Resolution State Committee standards of the Council of Ministers of the USSR dated July 27, 1973 No. 1843

Change No. 9 was adopted by the Interstate Council for Standardization, Metrology and Certification (Minutes No. 13 of May 28, 1998)

Registered by the Technical Secretariat of the IGU No. 2907

|

State name |

|

|

Republic of Belarus |

|

|

The Republic of Kazakhstan |

|

|

Republic of Kyrgyzstan |

Kyrgyzstandard |

|

The Republic of Moldova |

Moldovastandard |

|

Gosstandart of Russia |

|

|

The Republic of Tajikistan |

Tajikstandard |

|

Turkmenistan |

|

|

The Republic of Uzbekistan |

Uzgosstandart |

|

Ukraine |

State Standard of Ukraine |

Change No. 10 was adopted by the Interstate Council for Standardization, Metrology and Certification (Minutes No. 17 of June 22, 2000)

Registered by the Technical Secretariat of the IGU No. 3526

|

State name |

Name of the national standardization body |

|

The Republic of Azerbaijan |

Azgosstandart |

|

Republic of Belarus |

State Standard of the Republic of Belarus |

|

Georgia |

Gruzstandart |

|

The Republic of Kazakhstan |

Gosstandart of the Republic of Kazakhstan |

|

Republic of Kyrgyzstan |

Kyrgyzstandard |

|

The Republic of Moldova |

Moldovastandard |

|

Russian Federation |

Gosstandart of Russia |

|

The Republic of Tajikistan |

Tajikstandard |

|

Turkmenistan |

Main State Service "Turkmenstandartlary" |

3. INSTEAD GOST 2.107-68, GOST 2.109-68, GOST 5292-60 regarding section. VIII

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

In cases where product information is impossible or impractical to express in the form of an image or symbols, the graphic design document includes a text part, inscriptions and tables (GOST 2.316-68). The content of the text and inscriptions should be concise and precise. The text on the drawing field, tables, inscriptions related directly to the image are placed parallel to the main inscription.

The text part consists of technical requirements and technical characteristics. The text part is located above the main inscription (see Fig. 2.25). There should be no images, tables, etc. between the text part and the main text.

The technical requirements in the drawing are stated by grouping together information that is homogeneous and similar in nature, if possible in the following sequence:

a) requirements for the material, workpiece, technical processing and material properties of the finished part (electrical, magnetic, dielectric, hardness, humidity, etc.);

b) dimensions, maximum deviations of dimensions, shape and relative position of surfaces, mass, etc., not indicated in the graphic image;

c) requirements for the quality of surfaces, instructions on their finishing and coating;

d) gaps, location of individual structural elements;

e) requirements for setting up and regulating the product;

e) quality requirements

(click to view scan)

products: noiselessness, vibration resistance, etc.;

g) test conditions and methods;

h) instructions on marking and branding;

i) rules of transportation and storage;

j) special operating conditions;

Clauses of technical requirements must have continuous numbering. Each item is written on a new line.

The heading “Technical requirements” is written only if the drawing shows the technical characteristics of the product. The title is not underlined.

The technical characteristics are placed separately from the technical requirements on the free field of the drawing under the heading “ Technical specifications" The title is not underlined (see Figure 1.1).

When making a drawing on two or more sheets, the text part is placed only on the first sheet, regardless of which sheets contain the images that include the technical requirements or technical specifications.

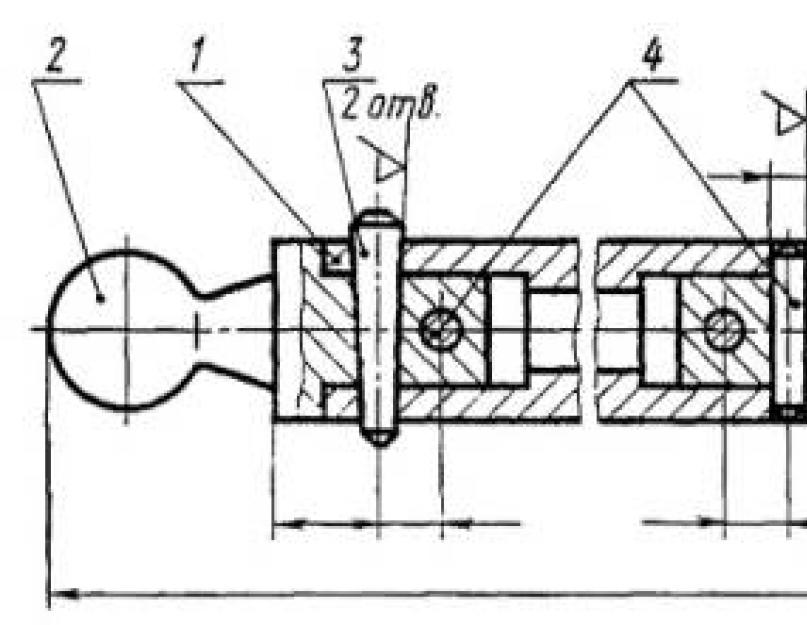

Labels related directly to the image may contain no more than two lines, located above or below the leader line shelf. These inscriptions contain information about the names of the component parts of the product (see Fig. 1.1), the number of structural elements (holes, grooves, etc.) (see Fig. 1.1, 1.2, 2.17, 2.27, 2.35).

A leader line that intersects the contour of the image and does not depart from any line ends with a dot (see Fig. 1.1, 2.35, 2.50).

The leader line, drawn from the line of the visible or invisible contour, as well as from the lines indicating the surface, ends with an arrow (see Fig. 1.3, 2.17, 2.45, 2.47, 2.48).

There should be neither an arrow nor a dot at the end of leader lines leading from all other lines (see Fig. 2.25, 2.41, 2.42).

Tables are placed in the free space of the drawing field to the right of the image or below it (see Fig. 2.25). The exception is tables of product parameters, for which the standard provides a specific place for its location in the drawing. For example, the table of parameters for a gear, worm, etc. is always located on the right top corner drawing (Fig. 2.51).

Tables are numbered within the drawing if there are references to them in the technical requirements, and the word “Table” with a serial number without a sign is placed on the right above the table. If there is only one table in the drawing, then it is not numbered and the word “Table” is not written.

GOST 2.316-68

INTERSTATE STANDARD

UNIFIED SYSTEM OF DESIGN DOCUMENTATION

RULES FOR APPLICATION ON DRAWINGS

INSTRUCTIONS, TECHNICAL REQUIREMENTS

AND TABLES

IPC PUBLISHING HOUSE OF STANDARDS

Moscow

INTERSTATE STANDARD

Approved by the Committee of Standards, Measures and Measuring Instruments under the Council of Ministers of the USSR in December 1967. The introduction date is set

from 01.01.71

1. This standard establishes the rules for applying inscriptions, technical requirements and tables on drawings of products from all industries.

(Changed edition, Amendment No. 1, 2,).

2. In addition to the image of the object with dimensions and maximum deviations, the drawing may contain:

a) text part consisting of technical requirements and (or) technical characteristics;

b) inscriptions indicating images, as well as those relating to individual elements of the product;

c) tables with dimensions and other parameters, technical requirements, control systems, symbols, etc.

3. The main inscription of the drawing must be made in accordance with the requirements of GOST 2.104-68 and GOST 2.109-73.

4. The text part, inscriptions and tables are included in the drawing in cases where the data, instructions and explanations contained in them are impossible or impractical to express graphically or by symbols.

6. Text in the drawing field, tables, inscriptions indicating images, as well as inscriptions associated directly with the image, as a rule, are placed parallel to the main inscription of the drawing.

7. Near the images on the shelves of leader lines, only short inscriptions are applied directly to the image of the object, for example, indications of the number of structural elements (holes, grooves, etc.), if they are not included in the table, as well as indications of the front side , rolling directions, fibers, etc.

8. A leader line that intersects the contour of the image and is not deviated from any line ends with a dot (Fig. 1 A) .

The leader line, drawn from the lines of the visible and invisible contour, as well as from the lines indicating surfaces, ends with an arrow (Fig. 1 b, V) .

At the end of the leader line, diverted from all other lines, there should be neither an arrow nor a dot (Fig. 1 G).

Crap. 1

(Changed edition, Amendment No. 1).

9. Leader lines should not intersect each other, be non-parallel to the hatch lines (if the leader line runs along a shaded field) and, if possible, not intersect dimension lines and image elements that do not include the inscription placed on the shelf.

It is allowed to make leader lines with one break (Diagram 2), as well as draw two or more leader lines from one shelf (Diagram 3).

Crap. 2

Crap. 3

10. Inscriptions related directly to the image may contain no more than two lines, located above and below the leader line shelf.

11. The text part placed on the drawing field is placed above the main inscription.

It is not allowed to place images, tables, etc. between the text part and the main inscription.

On sheets larger than A4, text may be placed in two or more columns. The column width should be no more than 185 mm.

The drawing leaves space for the continuation of the table of changes.

(Changed edition, ).

12. In the drawing of a product for which a table of parameters is established by the standard (for example, a gear, worm, etc.), it is placed according to the rules established by the corresponding standard. All other tables are placed in the free space of the drawing margin to the right of the image or below it and are carried out in accordance with GOST 2.105-95.

13. The technical requirements in the drawing are stated by grouping together requirements that are homogeneous and similar in nature, if possible in the following sequence:

a) requirements for the material, workpiece, heat treatment and material properties of the finished part (electrical, magnetic, dielectric, hardness, humidity, hygroscopicity, etc.), indication of substitute materials;

b) dimensions, maximum deviations of dimensions, shape and relative position of surfaces, mass, etc.;

c) requirements for the quality of surfaces, instructions on their finishing and coating;

d) gaps, location of individual structural elements;

e) requirements for setting up and regulating the product;

f) other requirements for product quality, for example: noiselessness, vibration resistance, self-braking, etc.;

g) test conditions and methods;

h) instructions on marking and branding;

i) rules of transportation and storage;

j) special operating conditions;

14. Clauses of technical requirements must have continuous numbering. Each item of technical requirements is written on a new line.

15. The heading “Technical requirements” is not written.

16. If it is necessary to indicate the technical characteristics of the product, it is placed separately from the technical requirements, with separate numbering of points, in a free field of the drawing under the heading “Technical characteristics”. In this case, the heading “Technical Requirements” is placed above the technical requirements. Both headings are not underlined.

17. When making a drawing on two or more sheets, the text part is placed only on the first sheet, regardless of which sheets contain the images to which the instructions given in the text part relate.

Inscriptions relating to individual elements of an object and placed on the shelves of leader lines are placed on those sheets of the drawing on which they are most necessary for ease of reading the drawing.

18. To designate images (types, sections, sections), surfaces, dimensions and other elements of the product in the drawing, capital letters of the Russian alphabet are used, with the exception of the letters Y, O, X, Ъ, ы, ь.

Letter designations are assigned in alphabetical order without repetition and, as a rule, without gaps, regardless of the number of sheets of the drawing. It is preferable to label the images first.

In case of a lack of letters, numerical indexing is used, for example: “A”; "A 1"; "A 2; "B-B"; "B 1 -B 1"; "B 2 -B 2."

Letter designations are not underlined.

(Changed edition, ).

19. The font size of letter designations should be approximately twice the size of the digits of the dimensional numbers used in the same drawing.

20. The scale of the image in the drawing, which differs from that indicated in the main inscription, is indicated immediately after the inscription relating to the image, for example:

A - A (1:1); B (5:1); A (2:1).

If in a drawing it is difficult to find additional images (sections, cuts, additional views, extension elements) due to the large saturation of the drawing or its execution on two or more sheets, then the designation of additional images indicates the sheet numbers or designations of the zones on which these images are placed (Fig. . 4).

Crap. 4

In these cases, above the additional images, their designations indicate the sheet numbers or designations of the zones on which the additional images are marked (Fig. 5).

It is recommended to provide the following data in the technical requirements on the drawings of welded structures:

1) brand of electrodes or filler wire.

Instead of the brand, it is allowed to indicate the type of electrode according to the corresponding state standards. It is allowed, instead of brands and types of electrodes and grades of filler wires, to indicate the necessary requirements for the strength and other properties of seams or welded joints;

2) information about the need for heat treatment of the welded structure after welding;

3) information about the need, restriction or prohibition of editing;

4) controlled seams or seam sections and the need for their control;

5) group of welded joints;

6) design and technological standards for the preparation and assembly of edges for welding and controlled dimensions of seams. They must comply with the requirements of regulatory and technical documents.

Below are examples of recordings technical requirements on drawings of welded structures.

For ordinary quality carbon steels (GOST 380-88), high-quality structural carbon steels (GOST 1050-88):

Welds according to GOST 5264-80.

2.

If the drawing contains standard and non-standard seams, then the technical requirements write:

1. Welding is carried out with an E42A electrode (GOST 9467-75).

Weld seams No....according to GOST 5264-80.

Welding seams No.... - manual arc.

It is allowed not to indicate welds in the drawing, especially for spatial structures made of angles, channels, etc.

For example:

... At the junction of parts made from channels, welding is carried out using T3 seams with a leg of at least 5 mm and C2 according to GOST 5264-80 along the entire length of contact of the parts.

...At the joints of parts made of sheets, welding with a C2 seam 50 mm long and with a pitch of 200 mm, welding of parts made of sheets to channels and flanges with a weld HI leg of at least 5 mm with a length of 50 mm with a pitch of 200 mm according to GOST 5264-80.

...At the junction of pipe parts, welding with a U5 seam with a leg of at least 5 mm in accordance with GOST 16037-80 along the entire length of contact of the parts.

...At the junction of pipe parts with channels, welding with a T1 seam with a leg of at least 5 mm in accordance with GOST 5264-80.

... At the junction of pipe parts with tape, welding is carried out using a HI seam no GOST 5264-80.

For alloyed structural steels (GOST 4543-71):

1. Welding is carried out with an E85A electrode (GOST9467-75).

2. Welds according to GOST 5264-80.

3. Group welds... (industry standard).

For corrosion-resistant steels according to GOST 5632-72 ( steel 12Х18Н10Т):

1. Welds according to GOST 14771-76.

2. Welding is carried out with filler wire Sv06Х19Н9Т GOST 2246-70.

3. Replacement with wire Sv04Х19Н11МЗ GOST 2246-70 is allowed.

4. Electric arc welding is allowed. Electrode E-08Х17Н8М2 GOST 10052-75.

5. Group welds... (industry standard).

If different welding methods are used in a welded structure, then in the technical requirements an entry should be made according to the type:

1. Electric arc welding electrode E-08Х20Н9Г2Б (GOST 10052-75). Electrode E-08Х17Н8М2 (GOST 10052-75) is allowed.

1. Group welds... (industry standard).

3. Welds made by electric arc welding should be monitored using the radiographic method in accordance with GOST 7512-82.

4. The remaining welds are made by argon arc welding with filler wire Sv06Kh19N9T (GOST 2246-70).

5. Welds made spot welding, groups... (industry standard).

If the assembly makes welds from aluminum alloys of various grades:

Welds in accordance with GOST 14806-80, except for seam No. 1.

Welding of seams No. 7 - No. 5 is carried out with filler wire SvAMts (GOST 7871-75).

Welding seam No. 1 - with filler wire SvAMgb (GOST 7871-75).

Group welds... (industry standard).

For titanium alloys (GOST 19807-91) ( OT4, VT1-00):

1. Argon arc welding.

Group welds... (industry standard).

2. Welding wire SVT4 OST1.90015-77.

Welding without filler wire is allowed.

3. Control welds using the radiographic method in accordance with GOST 7512-82.

4. After welding, perform straightening and annealing according to the instructions...

Impact straightening and straightening using static loads are not allowed.

For material VT14, if equal strength of the weld with the base material is required, then the technical requirements write:

Welding wire SvSPT-2 OST-1.90015-77.

Without presenting requirements for equal strength to weld seam:

Welding wire CvBT1-00 OST - 1.90015-77.

Solder connections

Soldered joints are permanent connections formed by the forces of molecular interaction between the parts being connected and the filler material called solder. Solder is an alloy (based on tin, copper, silver) or pure metal introduced in a molten state into the gap between the parts being connected. The melting point of solder is lower than the melting point of the materials of the parts. The design of soldered joints is similar to welded ones (Fig. 29, A - V). Lap joints are predominantly used. Butt joint and T-joints are used for low loads.

Fig.29

Unlike welding, soldering allows you to join not only homogeneous, but also dissimilar materials: ferrous and non-ferrous metals, alloys, ceramics, glass, etc.

When soldering, the surfaces of the parts are cleaned of oxides and degreased in order to obtain good wettability of the surface with solder and high-quality filling of gaps with it. Heating of solder and parts, depending on their size, is carried out with a soldering iron, gas torch, electric heating, in thermal furnaces, etc. To reduce the harmful effects of oxidation of the surface of parts during soldering, fluxes are used (based on borax, rosin, zinc chloride), and also soldered in a vacuum or in a neutral gas environment (argon). The molten solder spreads over the heated surfaces of the joints of the parts and, when cooled, hardens, firmly connecting the part.

The size of the gap in the joint determines the strength of the connection. With a small gap, the effect of capillary flow of solder is better manifested; the process of dissolution of part materials in molten solder extends to the entire thickness of the solder seam (the strength of the resulting solution is 30...60% higher than the strength of the solder).

The gap size is taken to be 0.03...0.2 mm, depending on the solder (low-melting or refractory) and the material of the parts.

Solder with a melting point of up to 400 °C is called low-melting solder. The most widely used are tin-lead and tin-lead antimony solders (POS90, POS61). These solders should not be used for connections operating at temperatures above 100 °C or subject to shock loads.

Solders with a melting point above 400 0 C are called refractory (silver or copper-based). Copper-based solders (VPr1, VPr2) are characterized by extreme fragility; they are used to connect parts loaded with static load. Silver solders (PSr40, PSr45) are used for critical connections. They are resistant to corrosion and are suitable for connecting parts subject to shock and vibration loads.

The advantage of soldered joints is the ability to connect dissimilar materials, resistance to corrosion, the ability to connect thin-walled parts, tightness, low stress concentration due to the high ductility of the solder. Soldering allows you to obtain connections between parts in hidden and hard-to-reach places in the structure.

The disadvantage of soldering compared to welding is its relatively low strength, the need for small and evenly distributed gaps between the parts being connected, which requires their precise machining and high-quality assembly, as well as pre-treatment surfaces before soldering.

The use of soldered joints in mechanical engineering is expanding due to the introduction of plastics, ceramics and high-strength steels, which are difficult to weld. Soldering is used to connect sheets, rods, pipes, etc. It is widely used in the automotive industry (radiators, etc.) and aircraft construction (plating with honeycomb intermediate filling). Soldering is one of the main types of connections in radio electronics and instrument making.

Calculation of the strength of solder joints is carried out using shear methods using strength of materials methods. It must be taken into account that in an overlap joint the area of the design section is equal to the contact area of the parts. For lap joints of low-carbon steel parts made with tin-lead solders (POS40), permissible shear stress [τ] With=60 N/mm 2.

Adhesive joints

Currently, permanent connections of metals and non-metallic materials obtained gluing. These are connections of parts with a non-metallic substance through surface adhesion and intermolecular bonding in the adhesive layer.

The most widely used adhesive joints are lap joints (Fig. 30), and less commonly, butt joints. Adhesive joints have made it possible to expand the range of use in machine designs of combinations of various heterogeneous materials - steel, cast iron, aluminum, copper, brass, glass, plastics, rubber, leather, etc.

Fig.30. Adhesive lap joint

The use of universal adhesives such as BF, VK, MPF and others (currently more than a hundred different brands of adhesives are used) makes it possible to increase the strength of adhesive joints to 80% in relation to the strength of the materials being glued. The most widely used in mechanical engineering are glued shear joints. The optimal thickness of the adhesive layer is 0.05…0.15 mm.

The strength of glued joints is influenced by the nature of the load, the design of the joint, the type and thickness of the adhesive layer (as the thickness increases, the strength decreases), gluing technology, and time (over time, the strength of some adhesives decreases).

The strength and density of the joint is ensured by good cleaning of the bonded surfaces and squeezing them at temperatures from 15 to 100 ° C, followed by holding from several minutes to several hours.

INTERSTATE STANDARD

|

one system design documentation RULES FOR APPLICATION ON DRAWINGS Unified system for design documentation. |

GOST in part of section. VI and 4. The text part, inscriptions and tables are included in the drawing in cases where the data, instructions and explanations contained in them are impossible or impractical to express graphically or by symbols. 6. Text in the drawing field, tables, inscriptions indicating images, as well as inscriptions associated directly with the image, as a rule, are placed parallel to the main inscription of the drawing. 7. Near the images on the shelves of leader lines, only short inscriptions are applied directly to the image of the object, for example, indications of the number of structural elements (holes, grooves, etc.), if they are not included in the table, as well as indications of the front side , rolling directions, fibers, etc. 8. A leader line that intersects the contour of the image and is not deviated from any line ends with a dot (Fig. 1 A). The leader line, drawn from the lines of the visible and invisible contour, as well as from the lines indicating surfaces, ends with an arrow (Fig. 1 b, V). At the end of the leader line, diverted from all other lines, there should be neither an arrow nor a dot (Fig. 1 G). (Changed edition, Amendment No. 1). 9. Leader lines should not intersect each other, be non-parallel to the hatch lines (if the leader line runs along a shaded field) and, if possible, not intersect dimension lines and image elements that do not include the inscription placed on the shelf. It is allowed to make leader lines with one break (Diagram 2), as well as draw two or more leader lines from one shelf (Diagram 3). 10. Inscriptions related directly to the image may contain no more than two lines, located above and below the leader line shelf. 11. The text part placed on the drawing field is placed above the main inscription. It is not allowed to place images, tables, etc. between the text part and the main inscription. On sheets larger than A4, text may be placed in two or more columns. The column width should be no more than 185 mm. The drawing leaves space for the continuation of the table of changes. 12. In the drawing of a product for which a table of parameters is established by the standard (for example, a gear, worm, etc.), it is placed according to the rules established by the corresponding standard. All other tables are placed in the free space of the drawing field to the right of the image or below it and are carried out in accordance with GOST 2.105-95. 13. The technical requirements in the drawing are stated by grouping together requirements that are homogeneous and similar in nature, if possible in the following sequence: a) requirements for the material, workpiece, heat treatment and material properties of the finished part (electrical, magnetic, dielectric, hardness, humidity, hygroscopicity, etc.), indication of substitute materials; b) dimensions, maximum deviations of dimensions, shape and relative position of surfaces, mass, etc.; c) requirements for the quality of surfaces, instructions on their finishing and coating; d) gaps, location of individual structural elements; e) requirements for setting up and regulating the product; f) other requirements for product quality, for example: noiselessness, vibration resistance, self-braking, etc.; g) test conditions and methods; h) instructions on marking and branding; i) rules of transportation and storage; j) special operating conditions; 14. Clauses of technical requirements must have continuous numbering. Each item of technical requirements is written on a new line. 15. The heading “Technical requirements” is not written. 16. If it is necessary to indicate the technical characteristics of the product, it is placed separately from the technical requirements, with separate numbering of points, in a free field of the drawing under the heading “Technical characteristics”. In this case, the heading “Technical Requirements” is placed above the technical requirements. Both headings are not underlined. 17. When making a drawing on two or more sheets, the text part is placed only on the first sheet, regardless of which sheets contain the images to which the instructions given in the text part relate. Inscriptions relating to individual elements of an object and placed on the shelves of leader lines are placed on those sheets of the drawing on which they are most necessary for ease of reading the drawing. 18. To designate images (types, sections, sections), surfaces, dimensions and other elements of the product in the drawing, capital letters of the Russian alphabet are used, with the exception of the letters Y, O, X, Ъ, ы, ь. Letter designations are assigned in alphabetical order without repetition and, as a rule, without gaps, regardless of the number of sheets of the drawing. It is preferable to label the images first. In case of a lack of letters, numerical indexing is used, for example: “A”; "A 1"; "A 2; "B-B"; "B 1 -B 1"; "B 2 -B 2." Letter designations are not underlined. (Changed edition, Amendment No. 3). 19. The font size of letter designations should be approximately twice the size of the digits of the dimensional numbers used in the same drawing. 20. The scale of the image in the drawing, which differs from that indicated in the main inscription, is indicated immediately after the inscription relating to the image, for example: A - A (1:1); B (5:1); A (2:1). If in a drawing it is difficult to find additional images (sections, cuts, additional views, extension elements) due to the large saturation of the drawing or its execution on two or more sheets, then the designation of additional images indicates the sheet numbers or designations of the zones on which these images are placed (Fig. . 4). In these cases, above the additional images, their designations indicate the sheet numbers or designations of the zones on which the additional images are marked (Fig. 5). 21. (Excluded. Amendment No. 3.) APPLICATION LIST OF ACCEPTABLE ABBREVIATIONS OF WORDS USED IN BASIC INSCRIPTIONS

Note : Abbreviations marked with “*” are used only in the title block. (Changed edition. Amendment No. 3). |